SLICERS

BSI-75 & BSI-75B Slicers

These slicers are capable of running up to 90 loafs per minute. These band slicers are designed for loaf bread and can run a variety of types. Over the years, we have made different improvements to this slicer, driven by customer needs and demands. These systems are often connected to automatic baggers but also can be used as a hand load and hand bag setup.

|

Flighted

Flighted Infeed Pros:

Flighted Infeed Cons:

|

Vertical Divider

|

Belted

Belted Infeed Pros:

Belted Infeed Cons:

| |||||||||||||||||||

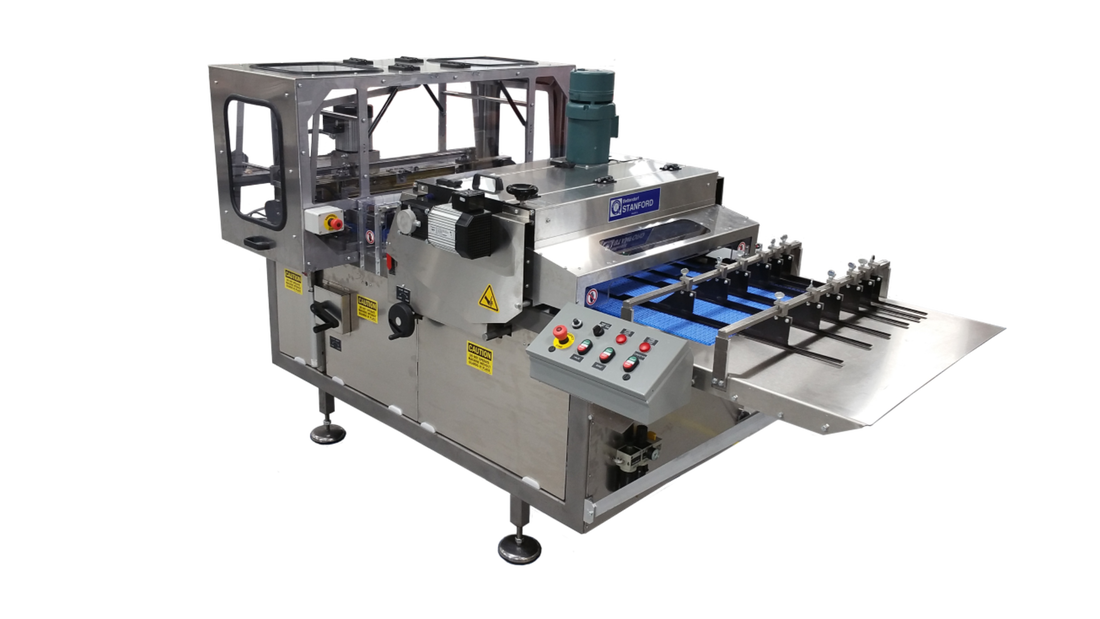

RSC - flighted/side beltOur reciprocating slicer has a fixed slice thickness which eliminates thick and thin slicing issues. However, this slice thickness can be adjusted in less than 5 minutes by swapping out the blade frame. This slicer can be connected to a hand bagger, deluxe hand bagger, or to a fully automatic bagger. This slicer is recommended for those hard to slice products like gluten-free breads, cinnamon raisin breads, breads with inclusions like nuts or fruit, dense hard crusted breads, and even the hard to slice pound cakes.

| |||||||

RSC - Top & Bottom beltedSame great RSC slicer as above, but with a top and bottom belted infeed system that allows this system to work great on hearth breads as well as nice pullman loaves.

|

|

Model 40 slicerThis slicer has the advanced features of the BSI 75 Slicer with a lower price point to suit lower production levels. Model 40 comes standard with belted top and bottom infeed belts and with an adjustable lattice which is capable of producing 34 slices from 3/8 to 3/4. This unit can be used for semi-automatic or fully automatic operations and is capable of producing up to 50 lpm. This machines works best for mid size bakeries and full scale artisan bakeries.

| |||||||

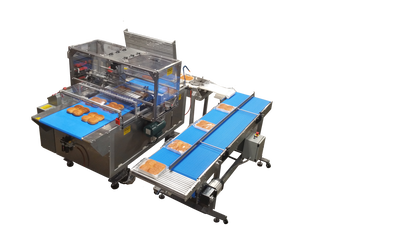

frozen slicerFrozen roll slicer for sandwich assembly. This slicer will slice a single row of frozen rolls such as English muffins, ciabatta, biscuits, or croissants at temperatures as low as 0 degree internal temp. After slicing, the rolls are separated so that the tops are sitting next to the bottoms for easy sandwich assembly.

|

|

hinge slicerOur hinge slicer can slice 2, 3, or 4 lane hinge or web slicing for small to medium size bakeries. We produce these slicers for individual or cluster products, bagels, hard rolls, and specialty rolls. We modify each slicer for the particular product that you are running. Our units can be used in conjunction with semi-automatic or automatic bagging.

|

hinge/band slicerCombines the Horizontal band slicer and the hinge slicer on one conveyor. This unit can be sold as a stand-alone slicer for hand loading and unloading or can be used with a hand bagger, a semi-automatic bagger, or can even be built as a replacement for the slicer section in an automatic bun line.

|

ultrasonic - conveyedOur ultrasonic is capable of slicing pound cakes, sheet cakes, and all types of round cakes.

|

ultrasonic - rotary |

crustless slicer

|

Standard Features:

Operational Features:

|

Safety Features:

|

half-cake slicer |

quarter cake slicer |

|

PH: 618-548-3555 Toll Free: 800-548-2253 |

1370 West Main Salem, IL 62881 |