|

Images and video shown with optional slicer, over-wrapper, and multi-pak bagger.

|

Servo-65 baggerOur Servo-65 Bagger is a scoop style bagger that is designed for bagging pan breads. This system is capable of bagging at speeds of up to 70 bags per minute. This all servo system uses 35% fewer moving parts than our BSI-55 mechanical scoop bagger.

Typically paired with a one of our BSI-75 or BSI-75B band slicers for normal breads, or our RSC slicer for hard to slice breads. These system combined can slice and bag anywhere from 45-65 bags per min. |

MAchine Capabilities |

Requirements |

|

|

Electrical Specifications

|

Mechanical Specifications

|

LAyouts

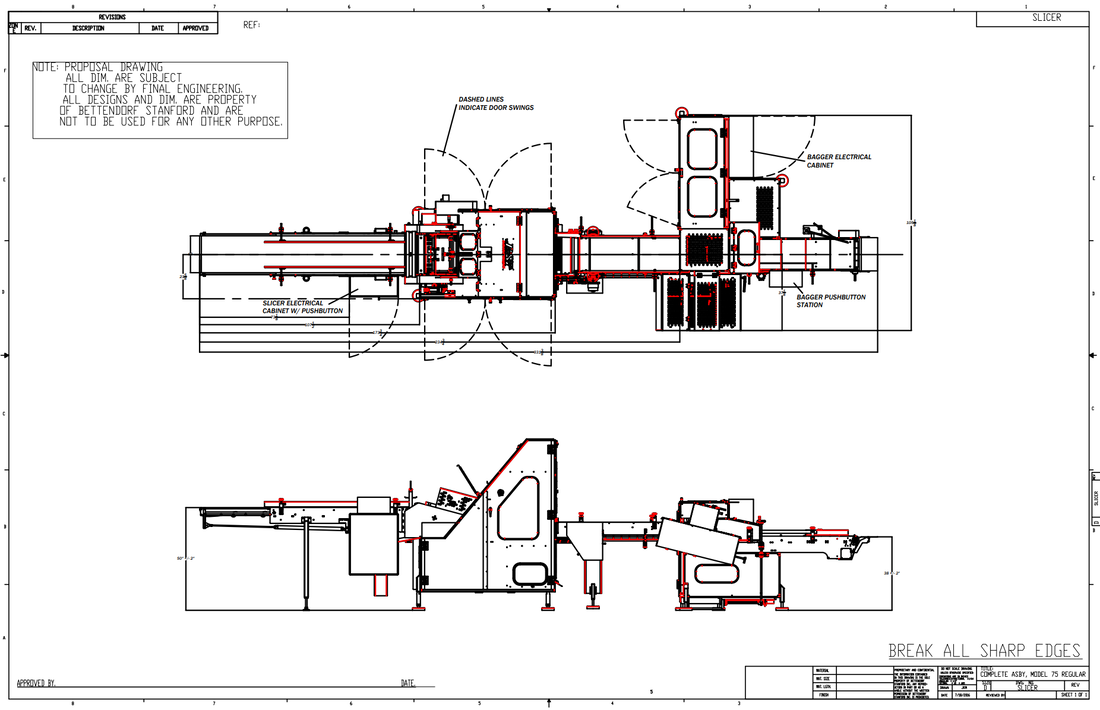

- Machine handing is based on operators standing position facing the machine.

- A Left Hand slicer and bagger would be product flowing from left to right

- A Right Hand slicer and bagger would be product flowing from right to left

- Left hand Servo-65 Bagger and BSI 75 Slicer shown below

| BSI-75 Slicer and Bagger LH Layout.pdf | |

| File Size: | 823 kb |

| File Type: | |

| BSI-75 Slicer and Bagger LH Layout.dxf | |

| File Size: | 11729 kb |

| File Type: | dxf |

| servo_65_bagger.pdf | |

| File Size: | 106431 kb |

| File Type: | |