|

|

Frozen HBSOur Frozen HBS is a slicer that is designed to slice frozen product, specifically for sandwich assembly lines. Typically used for biscuits, ciabatta, english muffins, and croissants. This unit takes a single lane of frozen product, slices it and separates it so that the top piece is sitting next to the bottom piece by the time the product exits the system. This exposes the cut surface of the bottom piece so that you can apply your egg, meat, cheese, or any other sandwich toppings with ease.

This system is the only one like it on the market. Our ability to slice AND separate frozen product puts this system way ahead of any other system out there. Their are other companies who may claim to be able to slice frozen product. In the end they wind up falling short because the product freezes back together after slicing and renders their systems unable to separate the tops from the bottoms. Then you are stuck having to waste time and labor slacking out product up to room temperature just so the system can properly process it. If the product comes to you frozen, dont waste energy thawing it out and then re-freezing it...simply keep it frozen. |

MAchine Capabilities |

Requirements |

|

|

Electrical Specifications

|

Mechanical Specifications

|

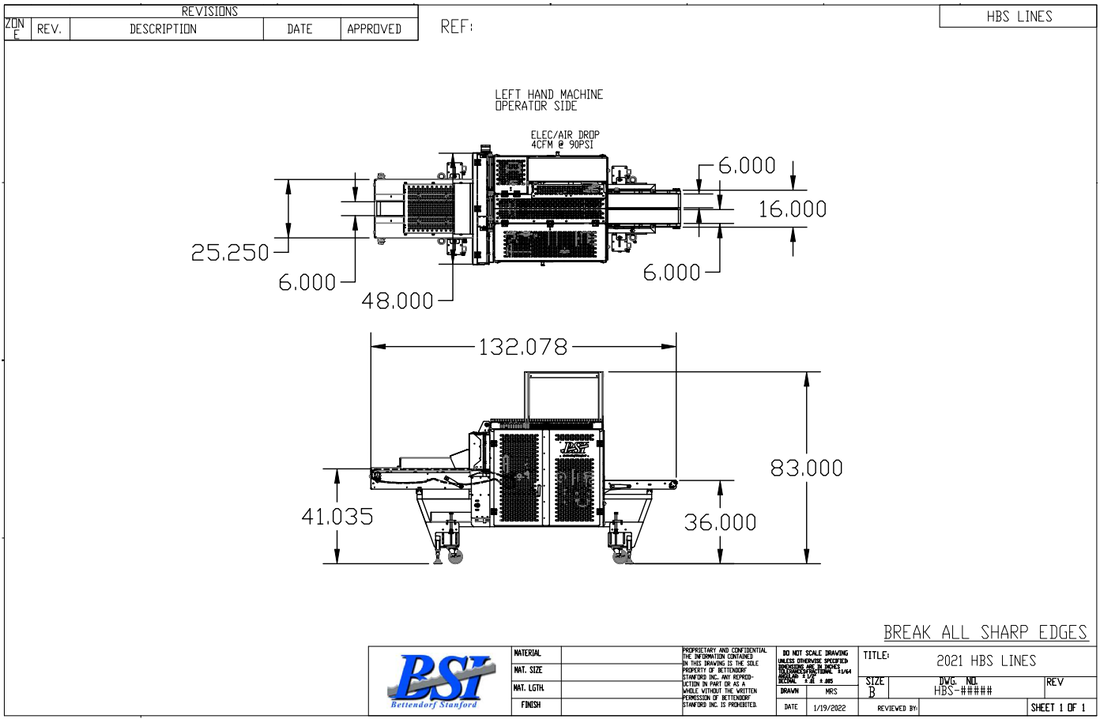

LAyouts

- A start stop station is positioned on the infeed and the discharge but the main control panel can be positioned on the left side as shown below or on the right side of the machine. (This change does not effect the dimensions of the system.)

- Even though the product goes in as one lane, you have the choice of having the top piece exiting to the right or the left side of the bottom piece. (This change does not effect the dimensions of the system.)

| 2021_hbs_layout.pdf | |

| File Size: | 523 kb |

| File Type: | |

| 2021_hbs_layout.dwg | |

| File Size: | 1454 kb |

| File Type: | dwg |