|

|

Model B BaggerOur Model B Bagger is a hand loaded automatic bagging system. Designed for operations that run product that varies too much in size from bun to bun for a full ALPS line, to bakeries who have simply outgrown their hand baggers and are ready to take that first leap into automation.

Designed to use one to two operators loading a variety of products from hamburger buns to hoagies, hots, rolls, croissants, or any other product you can fit in the system. You can also add one of our bun slicers in front of your new Model B Bagger for a more complete packaging room. |

MAchine Capabilities |

Requirements |

|

|

Electrical Specifications

|

Mechanical Specifications

|

LAyouts

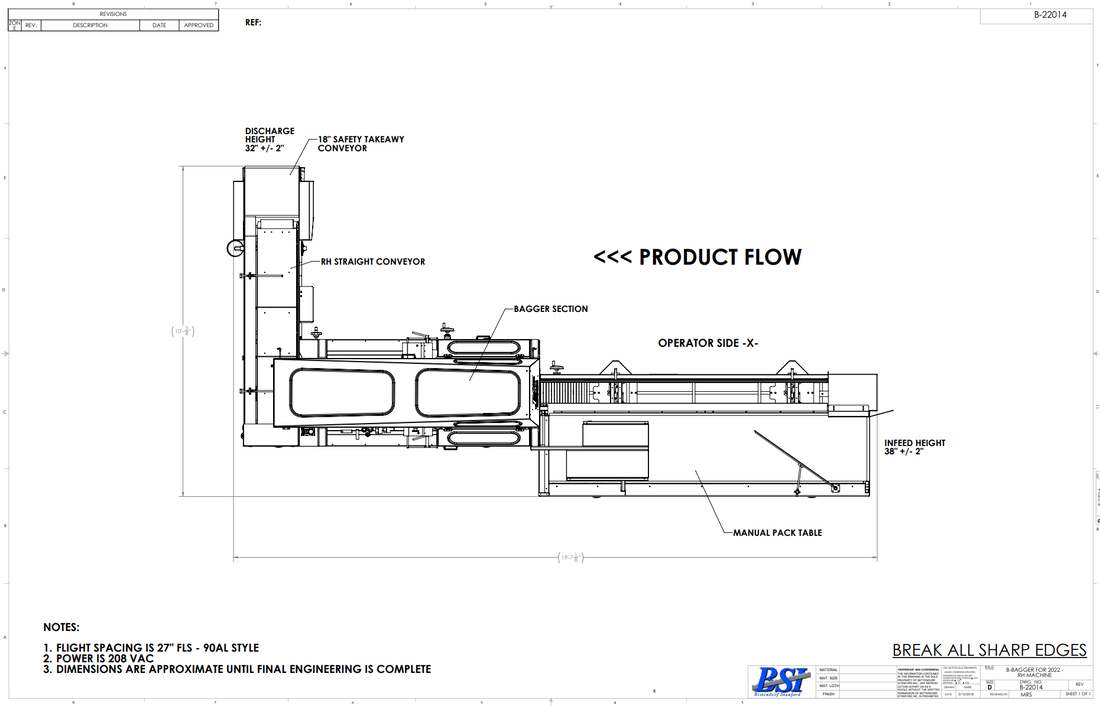

- Machine handing is based on operators standing position facing the machine.

- A Left Hand bagger would be product flowing from right to left

- A Right Hand bagger would be product flowing from left to right

- Handing of the discharge conveyor is based on the products point of view when leaving the bagger.

- If the product moves to the right when leaving the bagger it is a Right Hand Discharge

- If the product moves to the left when leaving the bagger it is a Left Hand Discharge

- Layout shown below is a Right Hand Bagger with a Right Hand Discharge

| Model B Layout.pdf | |

| File Size: | 246 kb |

| File Type: | |

| Model B Layout.dwg | |

| File Size: | 620 kb |

| File Type: | dwg |

| model_b_hand_load_bagger_brochure.pdf | |

| File Size: | 193340 kb |

| File Type: | |