|

|

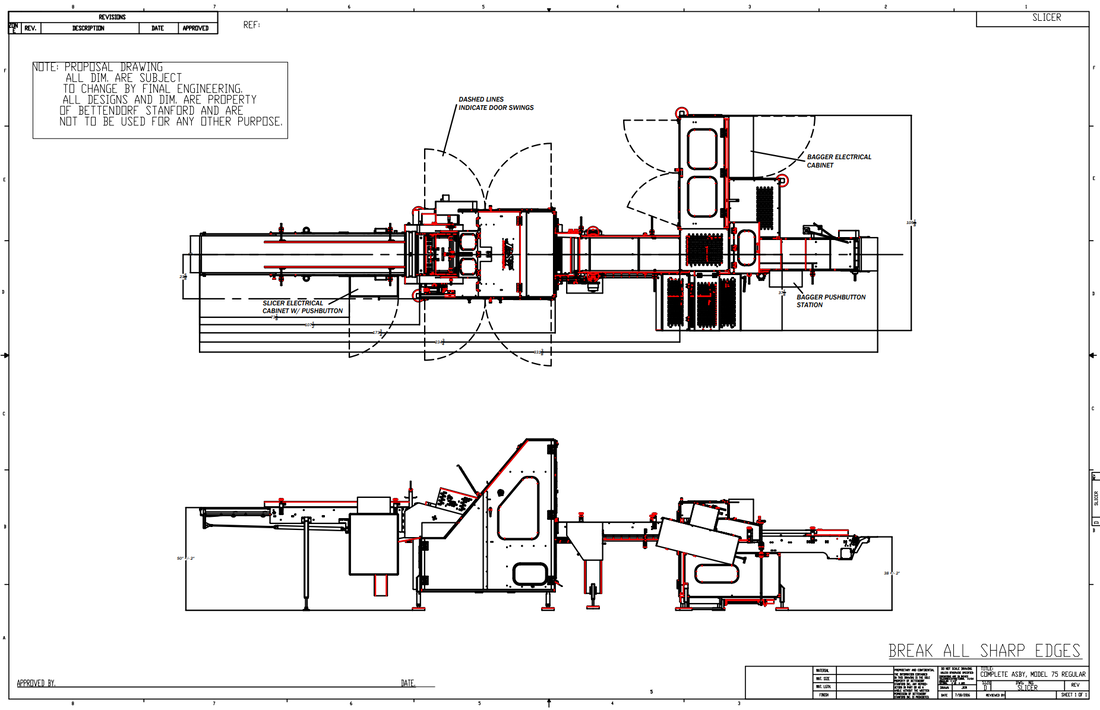

BSI-75B slicerOur BSI-75B slicer is a top and bottom belted infeed style band slicer. This slicer is designed for the high speed slicing of loaf bread. Capable of slicing at speeds that are only limited by how fast the bagger can bag.

BSI-75B slicers come with adjustable lattices to allow for different slicing ranges varying from 3/8" all the way up to 1". Standard lattice is 3/8"to 5/8" on a standard body and 3/8" to 1" on a wide body BSI-75B slicer. Available as a standard model or a Wide-body version. Wide version is 14" wider to allow for a full range of slice thickness adjustment with a full compliment of 21 blades. Typically paired with a BSI-55 or a Servo-65 bagger. These system combined can slice and bag anywhere from 45-65 bags per min. |

MAchine Capabilities |

Requirements |

|

|

Electrical Specifications

|

Mechanical Specifications

|

LAyouts

- Machine handing is based on operators standing position facing the machine.

- A Left Hand slicer and bagger would be product flowing from left to right

- A Right Hand slicer and bagger would be product flowing from right to left

- Left hand BSI-75 slicer and a BSI Bagger shown below

| BSI-75 Slicer and Bagger LH Layout.pdf | |

| File Size: | 823 kb |

| File Type: | |

| BSI-75 Slicer and Bagger LH Layout.dxf | |

| File Size: | 11729 kb |

| File Type: | dxf |

| bsi_75b_slicer_brochure.pdf | |

| File Size: | 147110 kb |

| File Type: | |