BAGGERS

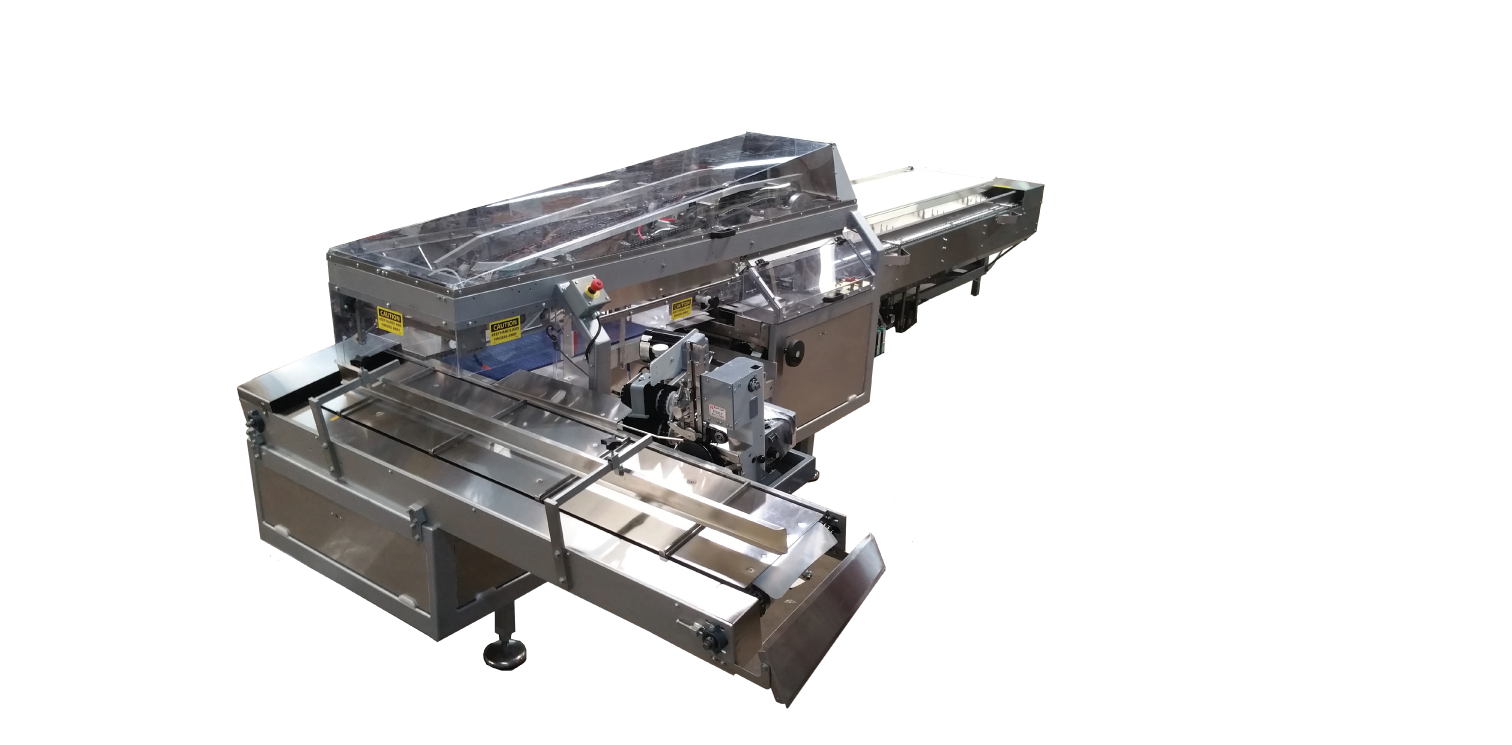

BSI-ALPS/ALPS-HSThe most reliable packaging line in the bun industry has been modified to run faster and more consistently than its predecessors.

Our machine is capable of continuously running cluster products at 60-66 ppm. The BSI-ALPS and ALPS-HS have been upgraded part by part to perform more efficiently day in and day out. All stainless steel framing, servo stackers, and a large range of enhanced features allow this machine to run to the highest bakery standards. |

|

BSI 55Scoop bagger for pan bread capable of running up to 60 loafs per minute (45-55 LPM recommended for continuous running speeds). This reciprocating style scoop bagger uses a traditional cam linkage system and open frame design for easy access.

|

Servo-65Scoop bagger for pan bread capable of running up to 70 loafs per minute (65 LPM recommended for continuous running speeds). This reciprocating style scoop bagger uses linear servos instead of the traditional cam linkage system to reduce moving components by 35%. Provides the same great open frame design as the BSI-55.

|

HAND BAGGER/DELUXE HAND BAGGER

This unit is designed for the hand bagging of a variety of products, such as bread and rolls.

|

Standard Features:

Safety Features:

|

Optional Accessories:

|

MODEL B BAGGERThis is the workhorse of the baking industry. From simple drive trains to complex sychronized controls, this bagger is designed to meet your needs and requirements. This bagger has been the industry standard for 30 plus years and its reliability and simplicity are unmatched. Most of the base units can run 45 to 50 ppm, while the newer,more integrated electronic units are capable of running 60 ppm.

|

MODEL LB BAGGEROne of our most versatile baggers...... the model LB bagger connects with a number of different machines for a wide variety of products and projects. This bagger uses a paddle to push product into a bag instead of pulling the bag back over the product. We recommend these baggers when running an inconsistent product or when trying to bag artisan breads.

|

Multipak

The multi-pak bagger is designed to apply a secondary bag over two or three individually bagged items.

|

Standard Features:

Maintenance Features:

|

Optional Features:

|

Multipak-b

|

Standard Features:

Maintenance Features:

Operational Features:

|

Optional Features:

|